In the realm of manufacturing, precision and efficiency are paramount. Automatic hinge assembly machines represent a pinnacle of technological innovation, revolutionizing the way hinges are manufactured and integrated into various products. These machines, purpose-built for the hinge assembly industry, offer a seamless blend of automation and precision engineering.

Introduction

Automatic hinge assembly machines, also known as hinge assembly systems, are sophisticated pieces of equipment designed to streamline the process of hinge integration in industrial settings. In essence, these machines automate the intricate task of assembling hinges, eliminating the need for manual intervention and ensuring consistent quality across production batches.

Design and Functionality

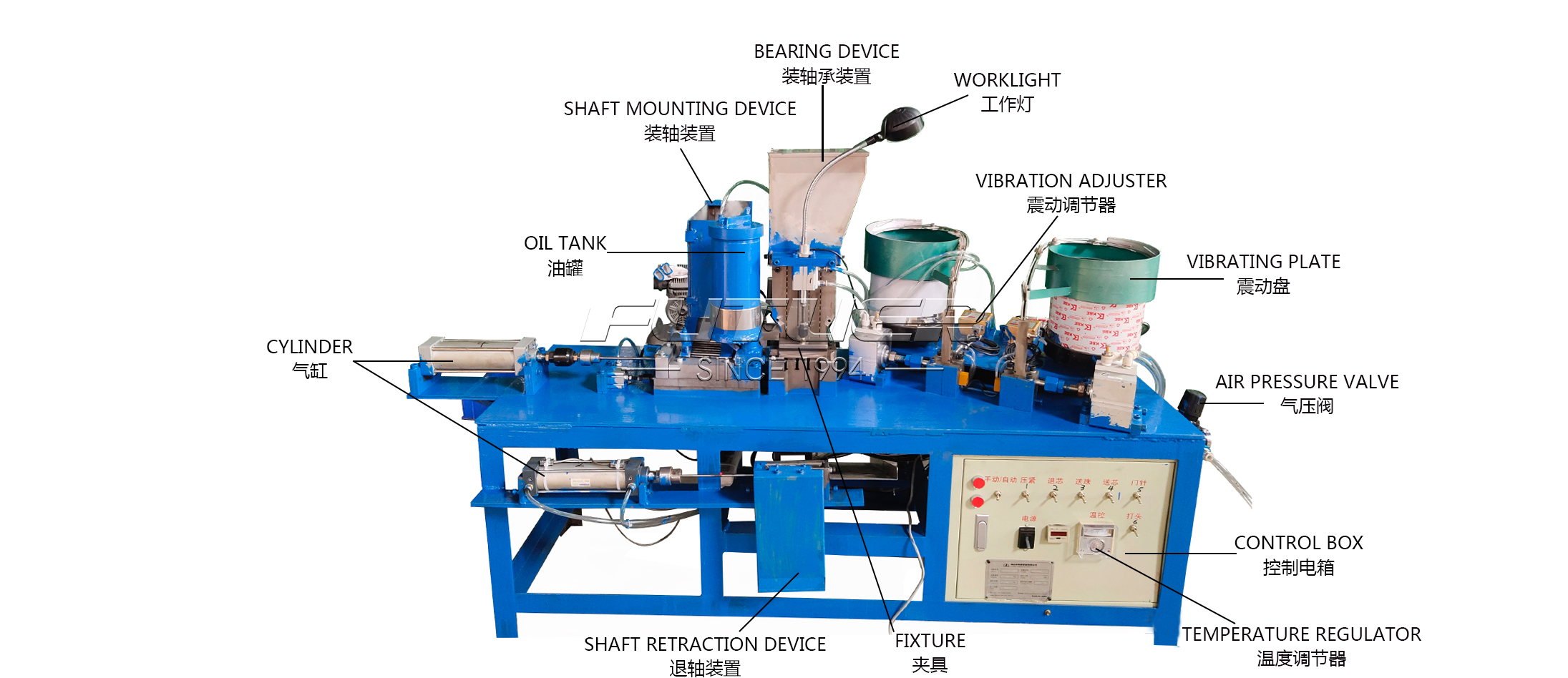

The engineering behind automatic hinge assembly machines is nothing short of remarkable. At their core, these machines leverage a complex array of mechanisms to facilitate seamless operation. The process begins with automatic feeding, where raw materials are precisely delivered to the assembly line. This is made possible through the integration of advanced feeding mechanisms that ensure a steady supply of materials without interruption.

Once the materials are in place, the machine springs into action, orchestrating the assembly and processing tasks with unparalleled efficiency. Every step of the assembly process is meticulously orchestrated, from aligning components to securing them in place with pinpoint accuracy. This integration of assembly and processing functions not only accelerates production but also enhances the overall precision of the assembly process.

Automated Detection and Material Handling

One of the standout features of automatic hinge assembly machines is their ability to detect and respond to changes in material availability. This is made possible through the implementation of sophisticated sensors and detection systems that constantly monitor the flow of materials. When the machine detects the presence of material, it automatically initiates the assembly process, ensuring a seamless workflow. Conversely, in the event of a material shortage, the machine halts operations and alerts operators, preventing costly production delays.

In addition to material detection, automatic hinge assembly machines excel in material handling and optimization. These machines are equipped with advanced material management systems that optimize material usage and minimize waste. By precisely controlling the amount of material used in each assembly, these machines help manufacturers reduce costs and improve overall efficiency.

Automatic Hinge Assembly Machine

Operation and Control

Despite their complexity, automatic hinge assembly machines boast intuitive user interfaces that simplify operation for operators of all skill levels. Central to this user-friendly design is the incorporation of touch screen technology, which provides operators with an intuitive interface for interacting with the machine. This streamlined interface not only enhances user experience but also contributes to overall safety by minimizing the risk of operator error.

Beyond simple operation, automatic hinge assembly machines offer robust performance monitoring and maintenance capabilities. These machines are equipped with automatic counting systems that track production output in real-time, allowing operators to easily monitor productivity levels. Additionally, the machines feature built-in alarming systems that alert operators to any anomalies or malfunctions, facilitating prompt troubleshooting and maintenance.

Applications and Industry Impact

The versatility of automatic hinge assembly machines extends beyond their primary function, making them indispensable assets in a wide range of industries. These machines are capable of accommodating various types of hinges, from simple door hinges to complex cabinet hinges, making them suitable for diverse applications. Furthermore, their adaptability to different production environments makes them ideal for manufacturers of all sizes, from small-scale operations to large-scale industrial facilities.

By streamlining the hinge assembly process, automatic hinge assembly machines play a crucial role in enhancing productivity and quality standards in the manufacturing industry. By automating repetitive tasks and minimizing human error, these machines enable manufacturers to achieve greater efficiency and consistency in their production processes. This not only translates to cost savings but also ensures that finished products meet stringent quality specifications, ultimately enhancing customer satisfaction.

Conclusion

Automatic hinge assembly machines represent a paradigm shift in the manufacturing industry, offering unparalleled efficiency, precision, and versatility. As technology continues to evolve, these machines will play an increasingly vital role in shaping the future of manufacturing, driving innovation and propelling the industry towards new heights of productivity and quality.