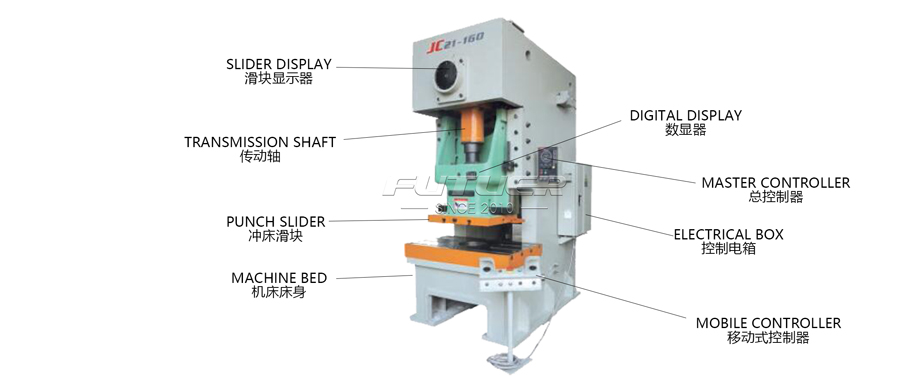

1. Adopt the crankshaft horizontal structure

2. Manual mold adjustment, scale display

3. All are equipped with an emergency braking device, which can make the slider stop suddenly within the range of 0°~135°, and a photoelectric protector is optional

Cutting, punching, blanking, bending, rolling, forming, stretching and other processes on the die.

—— STANDARD SIZES ——

Detailed parameters of the equipment

|

Specifications |

Unit |

JH21-80 |

JH21-110 |

JD21-125 |

JD21-160 |

JD21-200 |

|

|

Nominal capacity |

Kn |

800 |

1100 |

1250 |

1600 |

2000 |

|

|

Nominal pressure stroke |

mm |

5 |

6 |

6 |

6 |

6 |

|

|

Stroke of slide |

mm |

140 |

160 |

160 |

160 |

200 |

|

|

Strokes per minute |

Fixed |

min |

60 |

50 |

50 |

50 |

35 |

|

Variable |

|||||||

|

50-70 |

40-60 |

40-60 |

30-50 |

30-40 |

|||

|

Max.die set height |

mm |

320 |

350 |

350 |

350 |

450 |

|

|

Die set height adjustment |

mm |

80 |

80 |

80 |

110 |

110 |

|

|

Distance from slide center to frame |

mm |

300 |

350 |

350 |

380 |

390 |

|

|

Bolster(FB×LR) |

mm |

580*1000 |

680*1150 |

680×1150 |

740×1300 |

760*1400 |

|

—— EFFECT COMPARISON ——

Product comparison before and after forging

—— EQUIPMENT DETAILS ——

Detailed display of the product

—— EQUIPMENT SHIPMENT ——

Ships three or four times a week on average

—— FUTUER TEAM ——

About GUANGDONG FUTUER Machinery Co., Ltd.