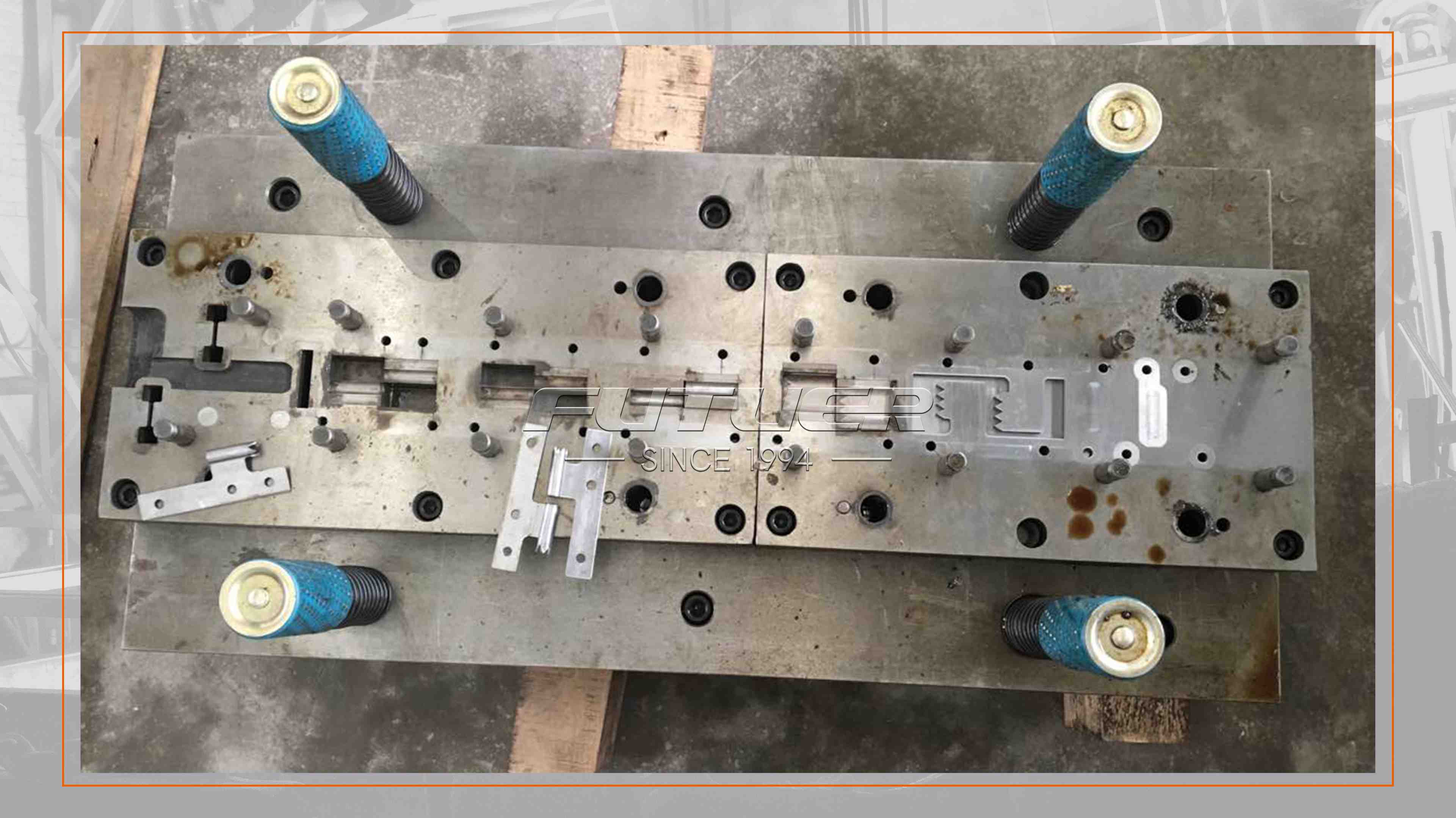

·Continuous progressive stamping

·Realize automatic feeding, punching, chamfering, pre-pressing and rolling on the mold, and one-time forming of the rolling

—— EFFECT COMPARISON ——

Product comparison before and after H hinge automatic mold

—— PRODUCT SIZE ——

H Hinge Automatic Mold Performance and Features

1) Equipment: We own Stamping machines, Hydraulic press machines, Auto-Turning machines, CNC-Turning machines, Milling machines,Precision wire cutting machines, more than 160 sets in total;

2) Material: iron, carbon steel, stainless steel, brass, copper, alloy steel, aluminum, cold rolled steel with various plating;

3) Surface treatment: kinds of plating (Zinc, Nikel, Chrome, Tin, Ag); Painting, Powder, Anodizing, E-coating, Silkscreen, Heat treatment, Black oxid;

4) Standard/ specification: OEM service as per customers' requests, within-house tooling design & fabricating;

5) RoHS compliance for export;

6) Quality assurance in accordance with ISO9001:2008;

7) Concurrent engineering capability on product design;

8) Just-in-time manufacturing capability to meet customer's requirement;

9) Tailor-made packaging method according to customer's requirement.

| Brand Name | OEM |

| Product Name | Metal Stamping Die/Mould |

| Tolerance | ±0.002mm |

| Material | SKD11, SKD 61, Cr12MOV, D2, SKH-9, RM56, ASP23 etc. |

| Design Software | AutoCAD, Solid works, PRO/E, UG |

| Standard | ISO9001 |

| Mould Type | Compound Stamping Die, Single Stamping Die, Progressive die or according to Customer’s requirements |

| First Trial | 15-25 days after mold drawing confirmed |

| Mould Life | Depends on customer’s production capacity |

| Quality confirm | Can send strip layout of die, testing video, inspection certificate and sample of product |

| Package | PE bags and carton for products, wooden case for Die/mold, or as customer's requirements |

—— EQUIPMENT DETAILS ——

Detailed display of the H hinge automatic mold

—— EQUIPMENT SHIPMENT ——

Ships three or four times a week on average

—— FURTURE TEAM ——

About GUANGDONG FUTUER Machinery Co., Ltd.