The metal stamping tooling is a tool used to make shaped items, and the shape of the item is mainly processed by changing the physical state of the formed material.

—— EFFECT COMPARISON ——

Product comparison before and after stamping die

—— PRODUCT SIZE ——

Mould Performance and Features

1) Equipment: We own Stamping machines, Hydraulic press machines, Auto-Turning machines, CNC-Turning machines, Milling machines,Precision wire cutting machines, more than 160 sets in total;

2) Material: iron, carbon steel, stainless steel, brass, copper, alloy steel, aluminum, cold rolled steel with various plating;

3) Surface treatment: kinds of plating (Zinc, Nikel, Chrome, Tin, Ag); Painting, Powder, Anodizing, E-coating, Silkscreen, Heat treatment, Black oxid;

4) Standard/ specification: OEM service as per customers' requests, within-house tooling design & fabricating;

5) RoHS compliance for export;

6) Quality assurance in accordance with ISO9001:2008;

7) Concurrent engineering capability on product design;

8) Just-in-time manufacturing capability to meet customer's requirement;

9) Tailor-made packaging method according to customer's requirement.

| Brand Name | OEM |

| Product Name | Metal Stamping Die/Mould |

| Tolerance | ±0.002mm |

| Material | SKD11, SKD 61, Cr12MOV, D2, SKH-9, RM56, ASP23 etc. |

| Design Software | AutoCAD, Solid works, PRO/E, UG |

| Standard | ISO9001 |

| Mould Type | Compound Stamping Die, Single Stamping Die, Progressive die or according to Customer’s requirements |

| First Trial | 15-25 days after mold drawing confirmed |

| Mould Life | Depends on customer’s production capacity |

| Quality confirm | Can send strip layout of die, testing video, inspection certificate and sample of product |

| Package | PE bags and carton for products, wooden case for Die/mold, or as customer's requirements |

—— EQUIPMENT DETAILS ——

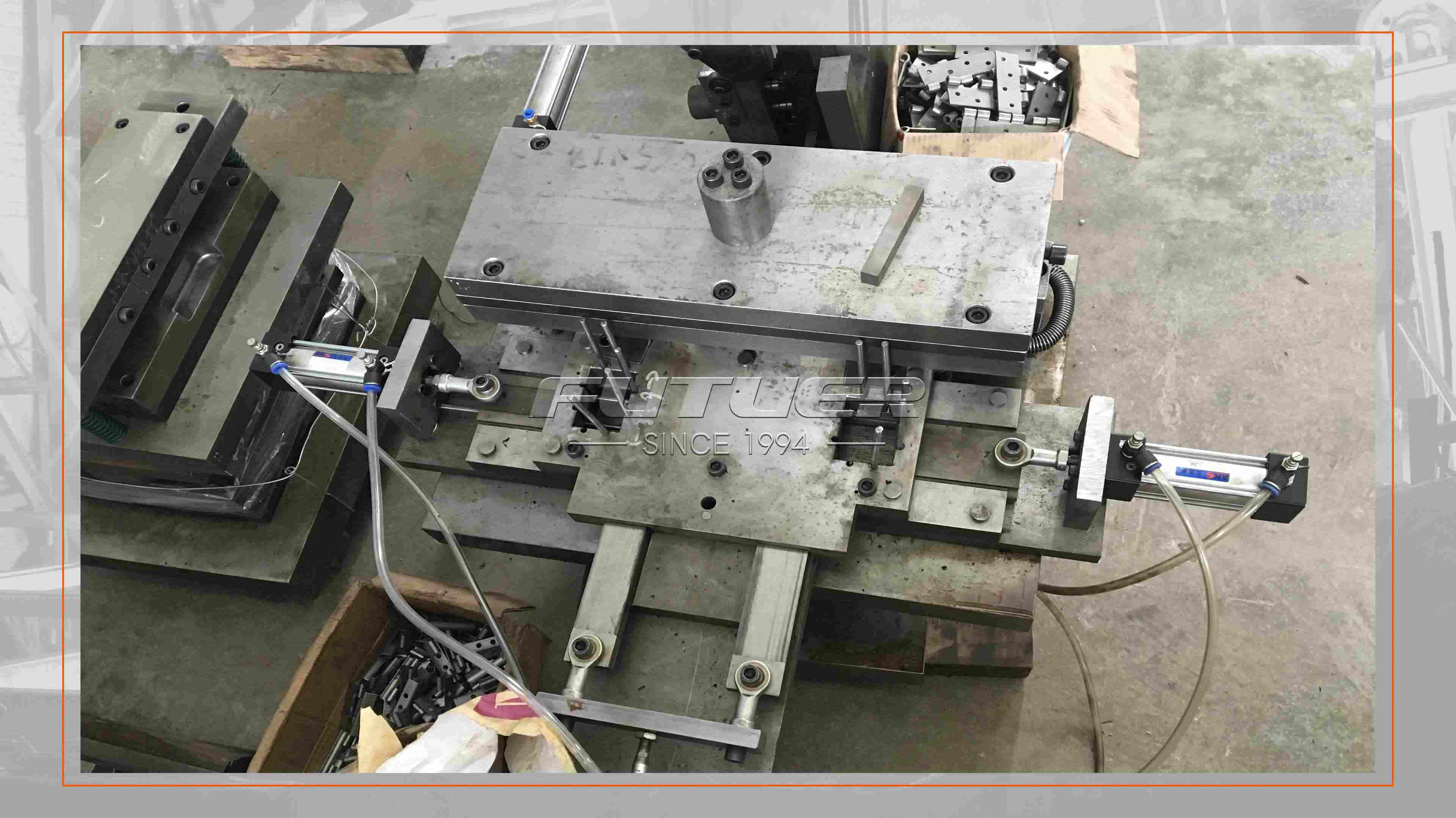

Detailed display of the stamping die

—— EQUIPMENT SHIPMENT ——

Ships three or four times a week on average

—— FURTURE TEAM ——

About GUANGDONG FUTUER Machinery Co., Ltd.