1, This machine has been integrated into the design and manufacturing with of our factor many years'experience,adwanced design concept and Process.

2, Use of CNC equipment to improving the size accuracy of the roller.

3,Due to the reasonable and accurate design and high precision of processing,the equipment has good stability and production.the products are stable and of high prescision.

4, Use the electrcity power saving punching machine,improve production efficiency and accuratey length.

5, Integrated part of antomatic control,easy to operate and high efficiency.

6, Punching holes can be punched out at one time and cut off and pressed.High-tech integrated production assembly and assembly,reducing man labor and improving production efficiency.

—— EFFECT COMPARISON ——

Product comparison before and after slide rail forming machine

—— PRODUCT SIZE ——

Slide Rail Forming Machine Performance and Features

| Voltage/Power | kw | U=200-240VAC/50-60HZ/5.5KW |

| Throughput | / | Intelligent length adjustment |

| Air Pressure | P | P=5-8KGF/CM2 |

| Capacity | min | 8-24 inches 35 bars/min |

| Weight | T | 4.5T |

| Dimension | mm | 5000x1850x620mm(L*W*H) |

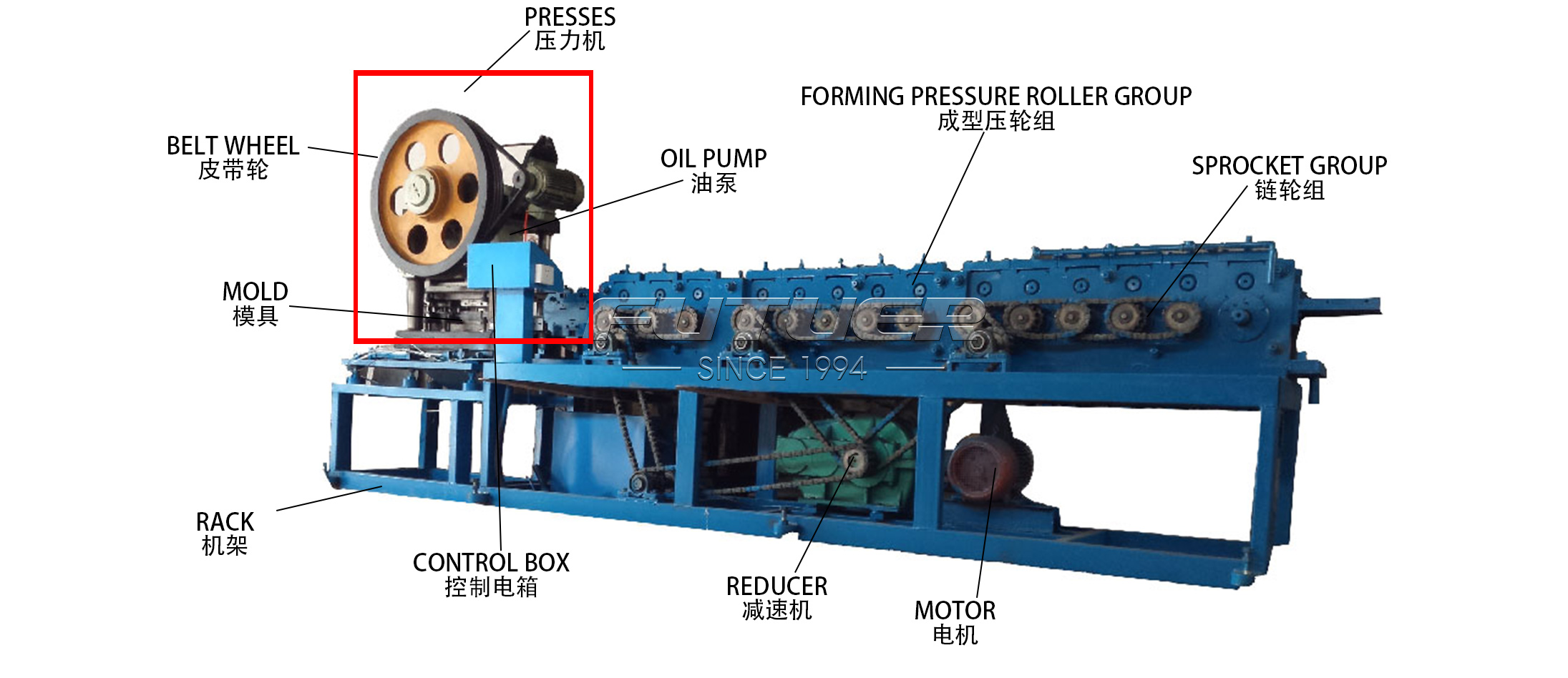

—— EQUIPMENT DETAILS ——

Detailed display of the slide rail forming machine

—— EQUIPMENT SHIPMENT ——

Ships three or four times a week on average

—— FURTURE TEAM ——

About GUANGDONG FUTUER Machinery Co., Ltd.