The automatic hinge polishing machine is a crucial innovation in many industries where meticulous craftsmanship and cutting-edge technology intersect. This article delves into more details of this remarkable equipment, exploring its definition, purpose, and the evolutionary journey that has made it an essential component of modern manufacturing.

Key Features of Automatic Hinge Polishing Machines

Precision Control Systems

Automatic hinge polishing machines have transcended traditional methods through the integration of advanced technology. This sophisticated addition empowers operators with unparalleled precision, allowing them to achieve the exact polish required for various hinge types. Automated calibration further refines this precision, ensuring consistent results with each cycle.

Versatile Polishing Tools

One size rarely fits all, and hinge polishing is no exception. These machines offer a myriad of abrasive wheel variations, catering to the diverse needs of different hinge materials and designs. Customizable configurations enable manufacturers to tailor the polishing process, ensuring a perfect finish every time.

Safety Measures

Safety is paramount in any industrial setting, and automatic hinge polishing machines are no exception. Enclosed workstations protect operators from potential hazards, while emergency shutdown systems provide a failsafe mechanism, offering peace of mind in high-paced manufacturing environments.

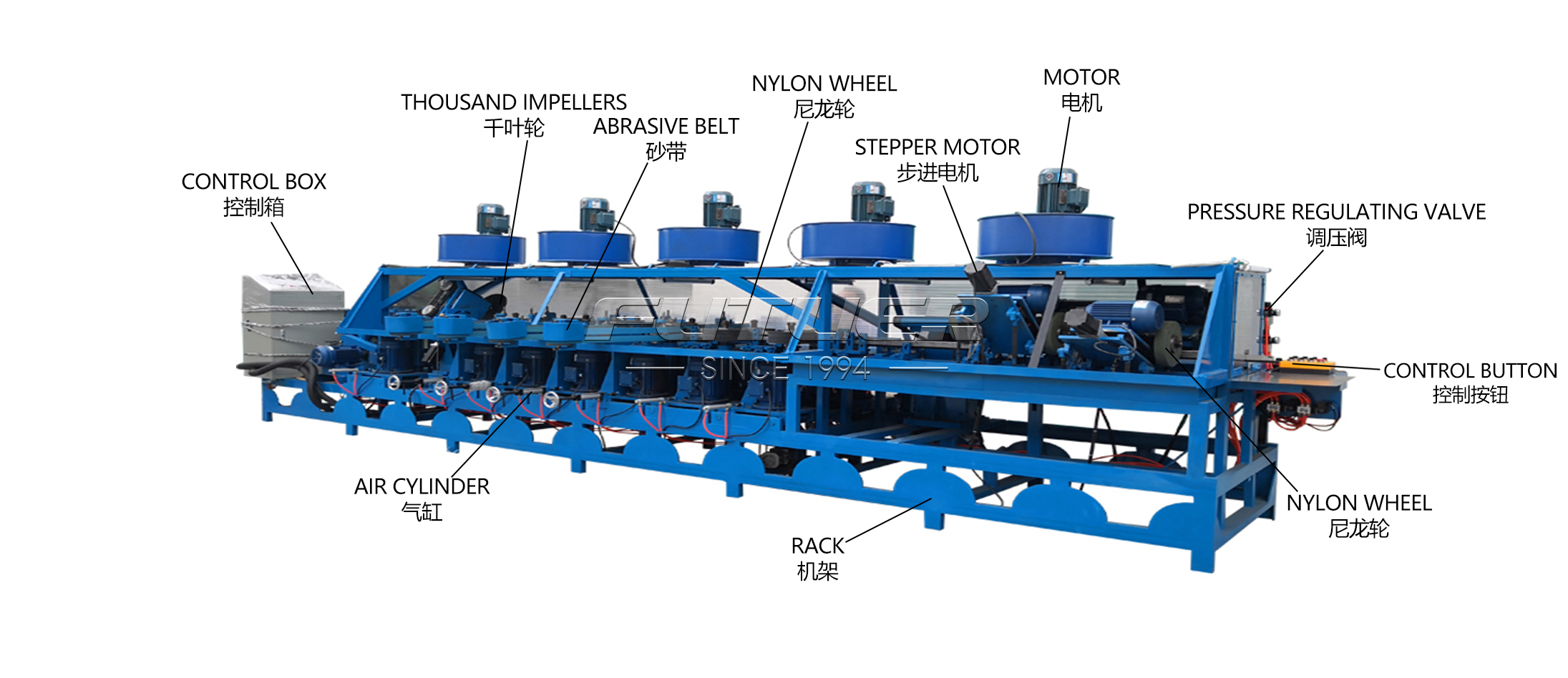

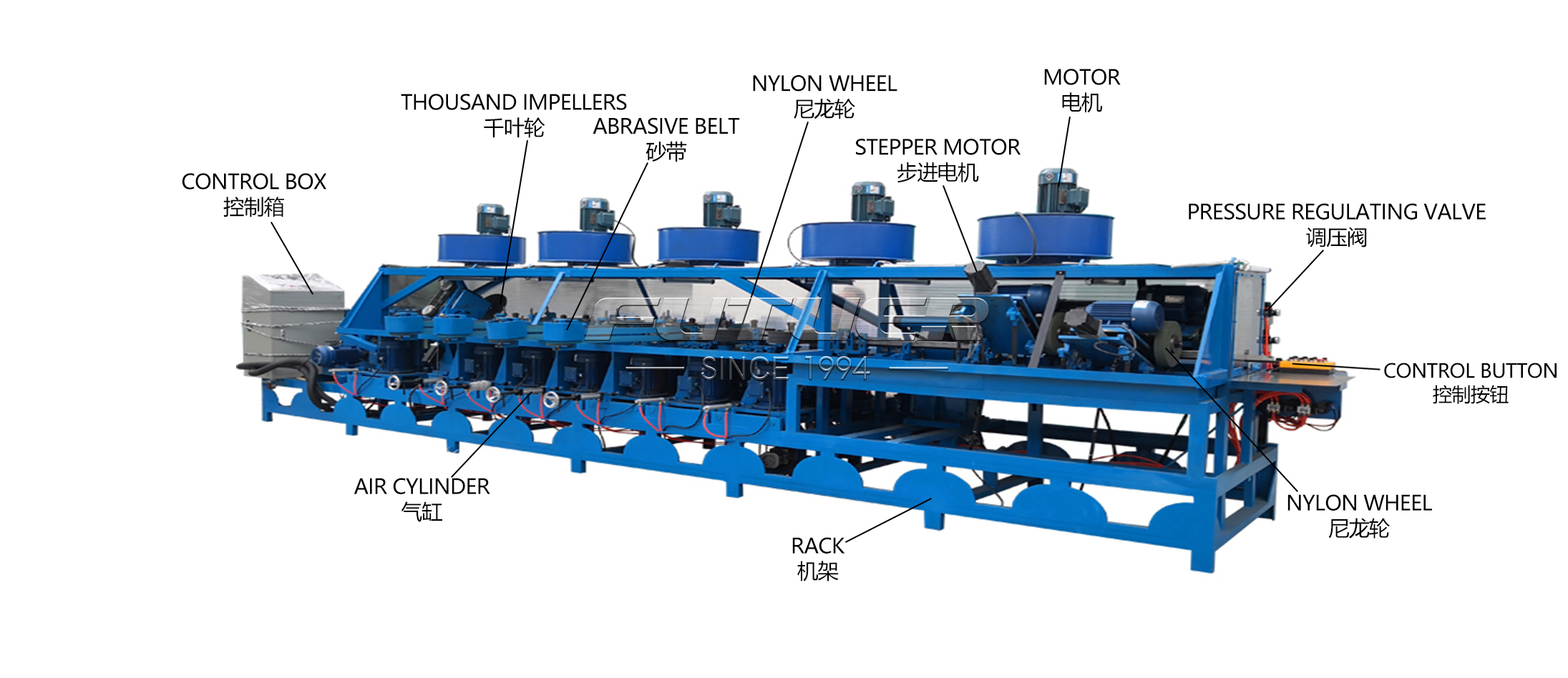

automatic hinge polishing machine

Advantages of Using Automatic Hinge Polishing Machines

Enhanced Efficiency

In a world driven by deadlines, these machines shine with their speed and throughput. Unlike manual polishing, which is labor-intensive and time-consuming, automatic hinge polishing machines can swiftly process numerous hinges without compromising on quality. Consistency is the name of the game, ensuring every hinge receives the same level of care.

Quality Improvement

Surface finish perfection is not just a buzzword; it's a reality with automatic hinge polishing machines. Their precision, coupled with advanced abrasive wheel options, leaves no room for imperfections. The result? Hinges that not only function flawlessly but also possess a visually stunning, mirror-like finish. Defects become a thing of the past.

Labor and Cost Savings

Automation is often synonymous with cost efficiency. With these machines, manufacturers can significantly reduce manual labor costs, redirecting resources to more value-added tasks. Moreover, maintenance costs are lower compared to the wear and tear associated with manual polishing methods.

Applications of Automatic Hinge Polishing Machines

Cabinet and Furniture Manufacturing

In the realm of cabinetry and furniture production, hinges are ubiquitous. Automatic hinge polishing machines are a game-changer, ensuring that every hinge enhances the overall aesthetics and functionality of the final product.

Automotive Industry

The automotive industry demands precision at every level. Automatic hinge polishing machines play a vital role in ensuring the longevity and reliability of hinges used in vehicles, contributing to passenger safety and comfort.

Aerospace Sector

In aerospace, the stakes are exceptionally high. Hinges in aircraft must meet stringent quality standards. Automatic hinge polishing machines are trusted allies in delivering the necessary precision and durability for this critical application.

Conclusion

The automatic hinge polishing machine marks a significant turning point in the manufacturing industry. Its accuracy, productivity, and adaptability make it a vital component in many different sectors. The days of manual hinge polishing are waning, and automation is paving the way for a new era of precision and excellence.

If you want more information about the automatic hinge polishing machine, please feel free to contact Futuer, China's top hinge equipment manufacturer. Send a message to info@futuer.cn and ask for a free quote today!