Drawer slide machines represent a technological leap in the world of furniture manufacturing and assembly. These ingenious devices have streamlined the process of incorporating drawer slides into cabinets and furniture, enhancing precision, efficiency, and overall product quality. In this article, we'll explore the significance of drawer slide machines, their functionalities, and how they contribute to the seamless construction of drawers in modern furniture.

The Evolution of Drawer Slides

Before delving into the specifics of drawer slide machines, let's briefly revisit the evolution of drawer slides. Traditionally, drawers were crafted with simple wooden runners or grooves, often resulting in friction and wear over time. The introduction of metal slides, equipped with ball bearings or rollers, marked a significant improvement in drawer functionality. However, the installation of these slides was a meticulous and time-consuming process.

The Birth of Drawer Slide Machines

Recognizing the need for increased efficiency in furniture assembly, manufacturers developed drawer slide machines. These machines are designed to automate and streamline the process of attaching drawer slides to cabinets, eliminating many of the challenges associated with manual installation.

The Working Mechanism

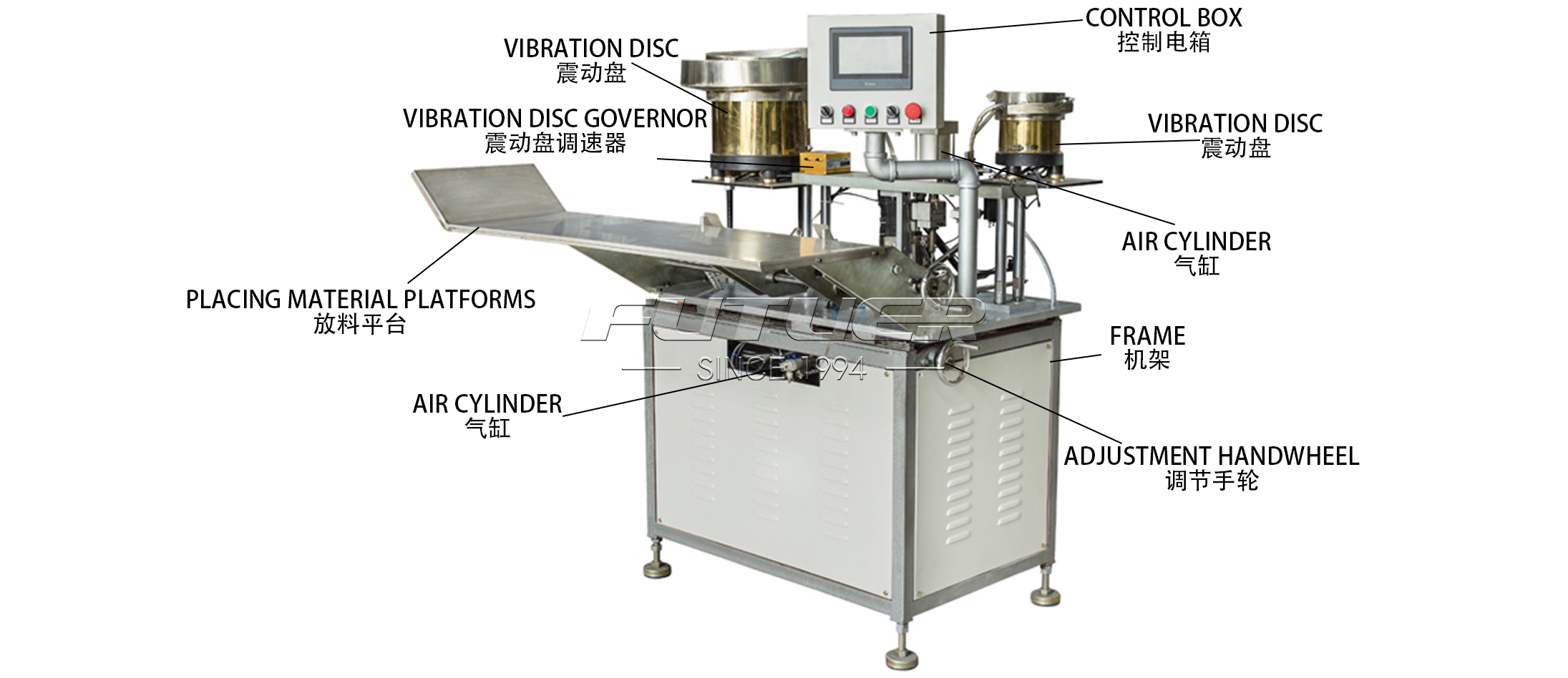

Drawer slide machines typically operate through a combination of robotics, sensors, and computerized controls. These components work in tandem to pick, position, and secure drawer slides with precision. Some machines are designed for specific slide types, while others offer flexibility to handle a range of slide variations.

Key Features of Drawer Slide Machines

Precision Alignment

Drawer slide machines excel in providing precise alignment of slides. This ensures that drawers glide smoothly without any wobbling or misalignment, contributing to the overall durability and functionality of the furniture.

Speed and Efficiency

One of the primary advantages of drawer slide machines is their ability to significantly reduce assembly time. These machines automate tasks that would traditionally be performed by hand, allowing for a faster and more efficient production process.

Consistency in Installation

Drawer slide machines contribute to consistent and standardized installation. This uniformity is crucial for large-scale furniture production, where maintaining quality across a batch of items is paramount.

Variety in Slide Types

Depending on the specific needs of furniture design, drawer slide machines can accommodate various types of slides, including ball-bearing slides, roller slides, and soft-close mechanisms. This adaptability makes these machines versatile in meeting diverse industry requirements.

Reduced Labor Costs

By automating the installation process, drawer slide machines help manufacturers reduce labor costs associated with manual assembly. This cost-effectiveness contributes to the overall competitiveness of furniture production.

Conclusion

Drawer slide machines represent a pivotal advancement in the field of furniture manufacturing, bringing efficiency, precision, and consistency to the assembly process. As technology continues to evolve, it's likely that these machines will become even more sophisticated, further enhancing the capabilities of the furniture industry. With their ability to streamline production and improve product quality, drawer slide machines are indeed revolutionizing the way we approach furniture construction in the modern era.