In today's industrial landscape, efficiency and precision are paramount. Among the various machines contributing to this efficiency is the filter brush making machine.

Importance of Filter Brushes in Various Industries

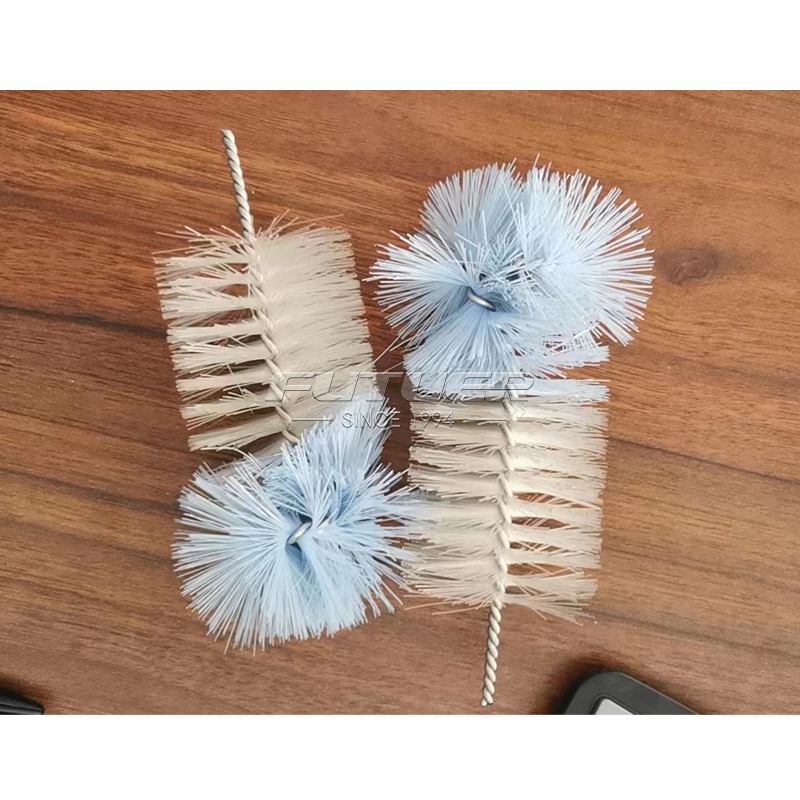

A filter brush making machine is a specialized apparatus designed to automate the production process of filter brushes. These brushes are essential components used in filtration systems across diverse industries.

Filter brushes play a critical role in maintaining cleanliness and efficiency in a wide range of applications, including air purification, water filtration, and industrial processes. As such, the efficiency and precision offered by filter brush making machines are invaluable.

Components of a Filter Brush Making Machine

Brush Fiber Feeding Mechanism

At the heart of the machine lies the brush fiber feeding mechanism. This component ensures a consistent supply of brush fibers, which are typically made of materials like nylon or polypropylene. The precision of this mechanism directly impacts the quality and uniformity of the final product.

Twisting and Trimming Unit

Once the fibers are fed into the machine, they undergo a series of processes in the twisting and trimming unit. Here, the fibers are twisted together to form the brush bristles, and excess material is trimmed to achieve the desired length and density.

Handle Attachment System

The handle attachment system is responsible for affixing handles to the completed brush heads. This process may involve techniques such as heat sealing or adhesive bonding, depending on the specific requirements of the application.

Working Mechanism of a Filter Brush Making Machine

Fiber Loading and Alignment

The first step in the operation of a filter brush making machine is the loading and alignment of brush fibers. This process ensures that the fibers are uniformly distributed and aligned before they enter the twisting and trimming unit.

Twisting and Trimming Process

Once the fibers are properly aligned, they are fed into the twisting and trimming unit, where they undergo controlled twisting and cutting actions. This process is crucial for achieving the desired density and uniformity of the brush bristles.

Handle Attachment Procedure

After the brush heads are formed, handles are attached to them in the handle attachment system. This final step completes the production process, resulting in fully assembled filter brushes that are ready for use.

Filter Brush Making Machine Applications

Applications and Benefits of Filter Brushes

Industrial Filtration Systems

Filter brushes find extensive use in industrial filtration systems, where they effectively capture contaminants and debris from liquids and gases. Their durability and efficiency make them indispensable in maintaining optimal performance in such systems.

HVAC Systems Maintenance

In HVAC (Heating, Ventilation, and Air Conditioning) systems, filter brushes play a crucial role in preventing the buildup of dust and debris on air filters. Regular maintenance with filter brushes ensures efficient airflow and prolongs the lifespan of HVAC equipment.

Environmental Remediation Projects

Filter brushes are also employed in environmental remediation projects, where they aid in the cleanup of contaminated soil and water. By efficiently trapping pollutants, filter brushes contribute to the restoration of ecosystems and the protection of public health.

Conclusion

The filter brush making machine stands as a testament to the marriage of innovation and practicality in modern industrial processes. With its ability to streamline production while maintaining high standards of quality, it serves as a cornerstone in various applications across industries.