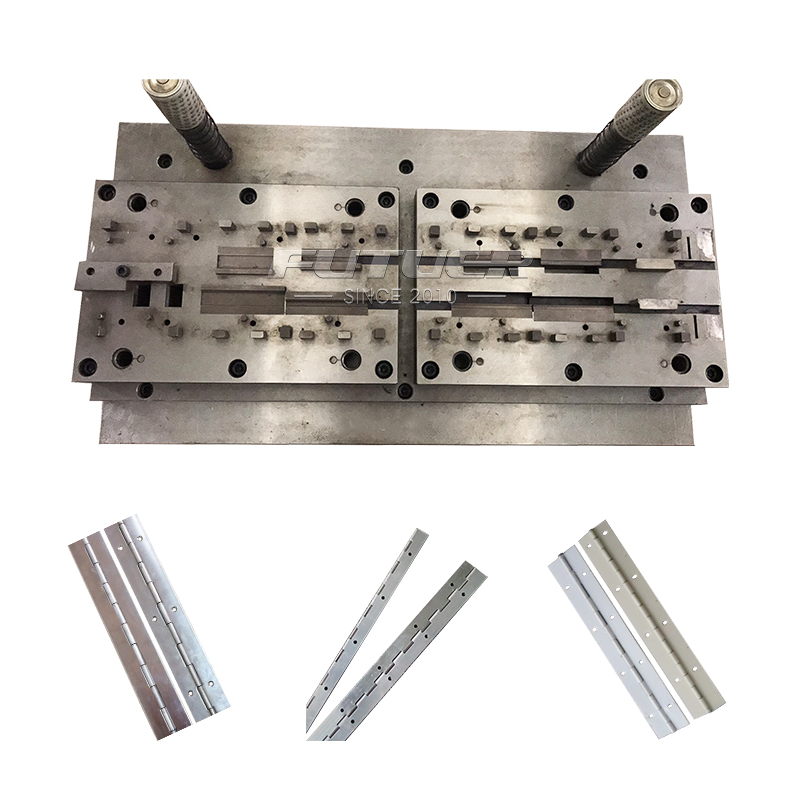

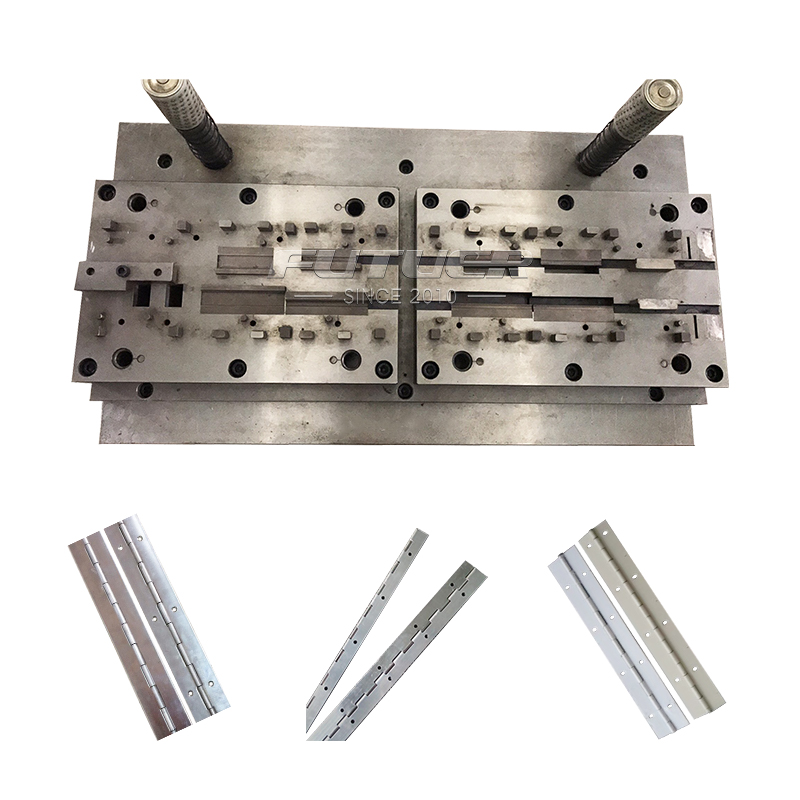

Piano hinges, known for their long, continuous design, have been pivotal components in various industries, ranging from aerospace to furniture. In the realm of manufacturing, the creation of precision piano hinge molds has been integral to producing consistent and high-quality products. With advancements in technology, the emergence of automatic piano hinge molds has revolutionized the manufacturing landscape, offering enhanced efficiency and precision.

The Functionality of Automatic Piano Hinge Molds

Automatic piano hinge molds function through intricate mechanisms and specialized components. These molds are designed to create seamless and uniform piano hinges with minimal human intervention. By employing automated processes, these molds ensure consistency and accuracy in every hinge produced.

The advantages over traditional molds are significant. Unlike traditional molds that rely heavily on manual labor and are prone to human error, automatic piano hinge molds operate with precision and reliability. The automation of the molding process not only reduces labor costs but also minimizes the risk of defects, thereby improving overall product quality.

Precision Engineering in Automatic Piano Hinge Molds

The cornerstone of automatic piano hinge molds lies in their precision engineering. These molds are engineered to meet stringent tolerances and exacting standards. Every component is meticulously designed and calibrated to ensure precise alignment and fit.

Tolerances and accuracy are paramount in automatic piano hinge molds. The ability to achieve tight tolerances ensures that each hinge meets precise specifications, leading to consistent performance and reliability. Furthermore, the use of advanced technologies, such as computer numerical control (CNC) machining, allows for unparalleled accuracy in every detail.

Material selection and durability play crucial roles in the functionality of automatic piano hinge molds. High-quality materials, such as hardened steel or aluminum alloys, are chosen for their durability and resistance to wear and tear. Through rigorous testing and analysis, engineers select materials that can withstand the rigors of continuous molding operations, ensuring longevity and performance.

Streamlining Manufacturing Processes with Automatic Piano Hinge Molds

The integration of automatic piano hinge molds into manufacturing processes streamlines operations in various ways. Efficiency gains are realized through reduced cycle times and increased throughput. By automating repetitive tasks, such as mold opening and closing, production rates are significantly enhanced, allowing manufacturers to meet growing demands with ease.

Cost-effectiveness and scalability are inherent benefits of automatic piano hinge molds. While the initial investment may be higher compared to traditional molds, the long-term savings are substantial. With lower labor costs and higher production efficiency, manufacturers can achieve a rapid return on investment. Additionally, the scalability of automatic piano hinge molds allows for seamless integration into existing production lines, making them ideal for both small-scale and large-scale manufacturing operations.

Conclusion

Automatic piano hinge molds represent a paradigm shift in manufacturing, offering unparalleled precision, efficiency, and reliability. Through precision engineering and advanced automation, these molds have transformed the production of piano hinges, setting new standards for quality and performance in the industry. As manufacturing continues to evolve, automatic piano hinge molds will undoubtedly play a pivotal role in shaping the future of production processes.