Cabinet hinges, often overlooked but indispensable, play a pivotal role in the functionality and aesthetic appeal of furniture. A seamless cabinet hinge production line is the backbone of ensuring these crucial components meet the standards of precision and durability. In this article, we delve into the cabinet hinge mold, exploring its definition, functionalities, and the significance of precision in its design.

Understanding Cabinet Hinge Mold

Cabinet Hinge Mold: Definition & Functionality

At the core of efficient cabinet hinge production lies the mold – a meticulously crafted apparatus that shapes the very essence of hinges. A cabinet hinge mold is a specialized tool designed to impart specific shapes and dimensions to the hinge components.

Precision in Mold Design for Hinge Production

Precision is the heartbeat of any well-crafted hinge, and it begins with the mold. Each contour, angle, and joint is a testament to the designer's skill in translating functionality into form. The meticulous nature of mold design ensures that the final product fits seamlessly into the cabinet structure, allowing for smooth operation and long-lasting performance.

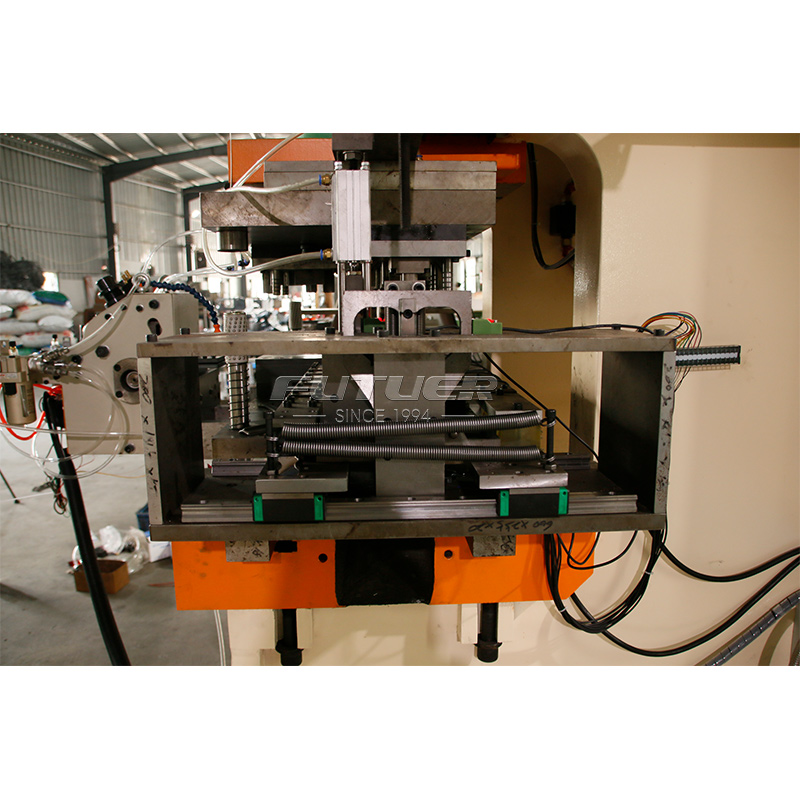

Metal Progressive Die Stamping Mold For Cabinet Hinge

Key Components of an Efficient Production Line

Mold Material Selection and Its Impact on End Product

The selection of materials for crafting the hinge mold is a critical decision that directly influences the quality of the end product. High-grade metals and alloys, such as stainless steel or aluminum, are often preferred for their durability and resistance to wear. The judicious choice of material not only enhances the mold's longevity but also imparts desirable characteristics to the cabinet hinge itself.

Advanced Technologies in CNC Machining for Hinge Molds

In the era of precision manufacturing, Computer Numerical Control (CNC) machining takes center stage in crafting cabinet hinge molds. This technology allows for unparalleled accuracy in shaping the mold components, ensuring that each hinge produced adheres to the specified design parameters. CNC machining, with its automated precision, streamlines the production process, resulting in consistency and efficiency.

Quality Control Measures in Hinge Mold Production

Inspection Protocols for Ensuring Mold Accuracy

Ensuring the accuracy of the mold is paramount to guaranteeing the quality of the cabinet hinge. Rigorous inspection protocols involving advanced measuring instruments and quality control checks are implemented at various stages of the mold production process. This meticulous scrutiny not only identifies potential flaws but also upholds the standardization crucial for mass production.

Addressing Tolerances and Dimensional Precision in Mold Crafting

Tolerances in hinge mold crafting are the fine threads that weave the fabric of perfection. Precise dimensional control, accounting for tolerances in micrometers, is essential to create hinges that seamlessly integrate into their designated spaces. The art of balancing tight tolerances with practical functionality defines the mastery behind crafting a flawless cabinet hinge mold.

Innovation and Trends in Cabinet Hinge Mold Production

Integration of 3D Printing in Mold Prototyping

Innovation is the driving force behind progress in hinge mold production. The integration of 3D printing in mold prototyping has revolutionized the industry, allowing for rapid iteration and testing of designs. This not only expedites the development process but also opens avenues for intricate and complex mold structures that were previously challenging to achieve.

Sustainable Practices in Mold Materials and Production Processes

In an age where sustainability is paramount, the cabinet hinge production line is not exempt from embracing eco-friendly practices. The adoption of sustainable mold materials and environmentally conscious production processes reflects an industry commitment to reducing its ecological footprint. The marriage of functionality and environmental responsibility is a trend that shapes the future of cabinet hinge mold production.

Conclusion

The nuanced interplay among technology, precision, and innovation delineates the realm of cabinet hinge production lines. Spanning from the adept craftsmanship in mold design to the forefront technologies shaping future advancements, the industry's evolution parallels the dynamic landscape of furniture design and manufacturing.

If you want further details about high-performance cabinet hinge mold for the cabinet hinge production line, please feel free to contact us at info@futuer.cn.