Cabinet hinge stamping die stands as an indispensable tool in the realm of manufacturing, particularly in the production of cabinets and furniture. At its core, this die facilitates the precise shaping and cutting of metal components that constitute hinges, ensuring uniformity and durability in the final product. Its significance reverberates through various industries where efficiency, precision, and quality are paramount.

Components of a Cabinet Hinge Stamping Die

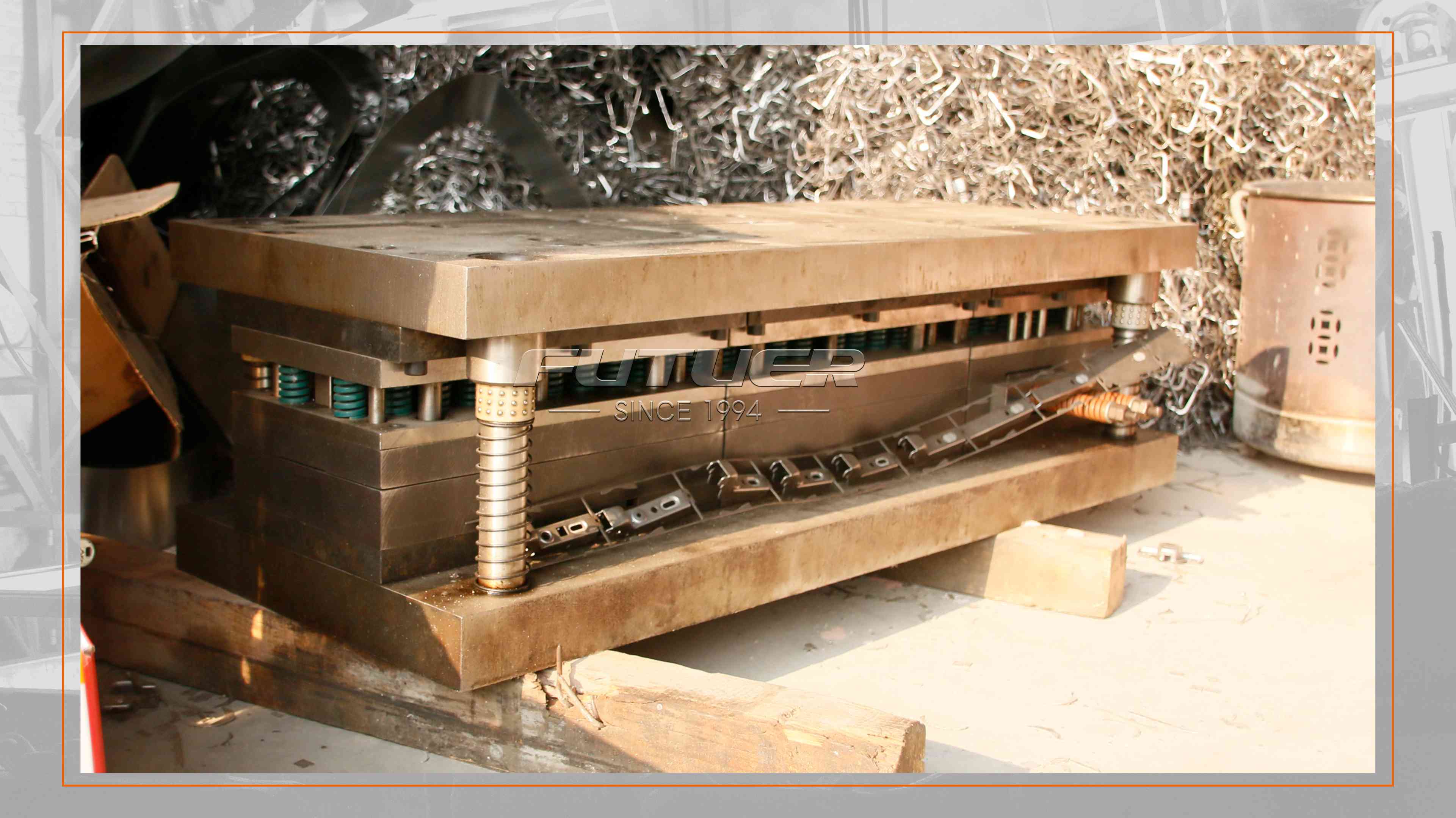

Die Plate

The die plate serves as the foundational component of the cabinet hinge stamping die, providing a stable platform for the stamping process. Typically crafted from hardened steel or other durable materials, the die plate withstands immense pressure and wear during operation. Its intricate design accommodates the specific dimensions and contours required for the desired hinge shape. Precision machining techniques are employed to ensure the die plate's accuracy and longevity, contributing to the overall efficiency of the stamping operation.

Punch and Die

Central to the stamping process is the punch and die, working in tandem to shape and cut the metal material into the desired hinge configuration. The punch exerts force onto the metal sheet, driving it into the die cavity to form the hinge shape. Both the punch and die undergo meticulous engineering to achieve optimal performance and durability. Variations in punch and die designs cater to diverse hinge specifications, allowing manufacturers to produce a wide range of cabinet hinges with unparalleled precision.

Stamping Process

Preparation

The stamping process begins with meticulous preparation, encompassing material selection and die setup. Manufacturers carefully choose the metal material best suited for the intended application, considering factors such as strength, corrosion resistance, and formability. Die setup involves configuring the stamping press and aligning the die components to ensure precise operation. Attention to detail at this stage lays the groundwork for a successful stamping operation.

Stamping Operation

Once preparation is complete, the stamping operation commences with the feeding of the metal sheet into the die cavity. A synchronized feed mechanism ensures consistent material flow, minimizing waste and optimizing production efficiency. As the press applies pressure, the punch and die work in concert to shape the metal sheet into the desired hinge configuration. Precision control systems monitor and regulate the stamping process, maintaining uniformity and accuracy in every stamped component.

Post-stamping Procedures

After stamping, thorough inspection and quality control measures are implemented to assess the integrity of the stamped hinges. Dimensional accuracy, surface finish, and structural integrity are scrutinized to ensure compliance with specifications and standards. Additionally, ongoing maintenance and care of the stamping die are essential to preserve its performance and longevity. Regular cleaning, lubrication, and periodic retooling prolong the die's service life, safeguarding the quality and efficiency of future stamping operations.

Advantages and Applications

Efficiency in Mass Production

The utilization of cabinet hinge stamping dies streamlines the manufacturing process, enabling rapid production of high-quality hinges on a mass scale. By automating the stamping operation, manufacturers significantly reduce production time and labor costs while maintaining consistent product quality. This efficiency translates into competitive advantages in the marketplace, allowing companies to meet consumer demands promptly and profitably.

Versatility in Design

One of the defining attributes of cabinet hinge stamping dies is their versatility in accommodating diverse design requirements. Manufacturers have the flexibility to customize hinge specifications, including dimensions, shapes, and features, to suit specific applications and aesthetic preferences. This adaptability empowers designers and engineers to innovate and differentiate their products, enhancing market competitiveness and customer satisfaction. Moreover, the consistency achieved through stamping ensures uniformity in product quality, reinforcing brand reputation and reliability.

Conclusion

Cabinet hinge stamping dies play a pivotal role in modern manufacturing, revolutionizing the production of cabinet hinges with unparalleled precision and efficiency. By harnessing advanced technologies and engineering expertise, manufacturers can optimize their stamping operations, delivering superior products that meet the demands of today's discerning consumers. As the manufacturing landscape continues to evolve, the cabinet hinge stamping die remains a cornerstone of innovation and excellence in the pursuit of quality craftsmanship.