Hinge auto polishing machines play a vital role in various industries where polished hinges are essential components. Let's delve into the intricacies of these machines and their significance in today's manufacturing landscape.

Understanding Hinge Auto Polishing Machines

Understanding how hinge auto polishing machines operate is crucial to grasping their significance. These machines employ advanced polishing techniques to achieve smooth and consistent finishes on hinges. They incorporate a range of components and mechanisms designed to automate the polishing process while maintaining high-quality standards.

Hinge auto polishing machines have become indispensable tools in industries where the quality of polished hinges directly impacts product performance and aesthetics. Whether it's automotive, manufacturing, or furniture, the demand for precise and efficient polishing solutions has propelled the popularity of these machines.

How Hinge Auto Polishing Machines Work

Hinge auto polishing machines utilize various polishing methods, including abrasive belts, wheels, or brushes, depending on the specific requirements of the hinges. These machines feature programmable controls that allow operators to adjust polishing parameters such as pressure, speed, and polishing media to achieve desired results.

Key Components of Hinge Auto Polishing Machines

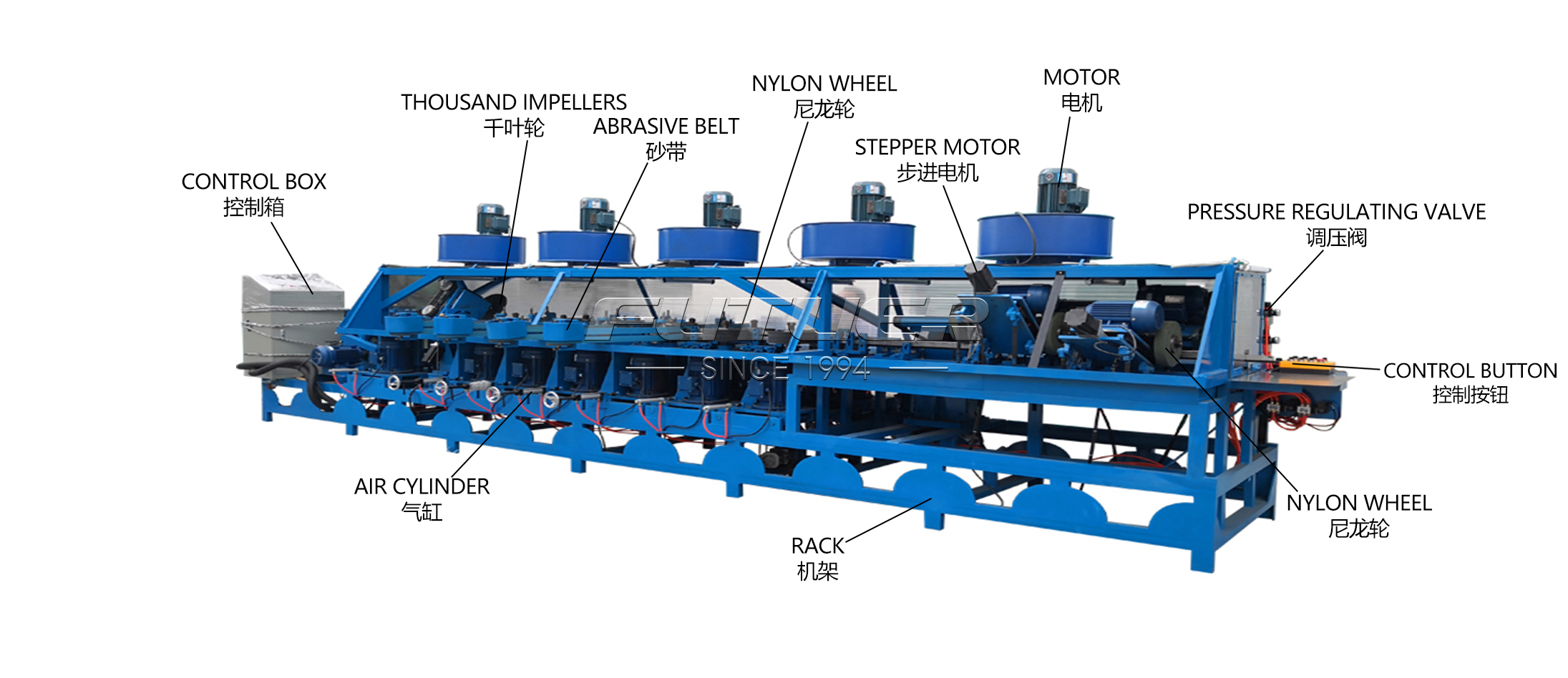

Key components of hinge auto polishing machines include polishing heads, conveyor systems, abrasive media reservoirs, and control panels. Each component plays a crucial role in ensuring precise and efficient polishing operations. Polishing heads, equipped with abrasive materials, exert controlled pressure on hinges as they pass through the machine, resulting in uniform polishing.

Automatic hinge polishing machine

Advantages of Using Hinge Auto Polishing Machines

The adoption of hinge auto polishing machines offers numerous advantages over traditional manual polishing methods.

Efficiency in Polishing Hinges

Hinge auto polishing machines significantly reduce polishing time and labor requirements compared to manual methods. By automating the polishing process, these machines can handle large volumes of hinges with minimal human intervention, thereby increasing overall productivity.

Consistency in Polishing Quality

One of the primary benefits of hinge auto polishing machines is their ability to deliver consistent polishing quality across all hinges. With programmable controls and precise polishing parameters, these machines eliminate variations in polishing results commonly associated with manual polishing techniques.

Cost-effectiveness Compared to Manual Polishing Methods

While the initial investment in hinge auto polishing machines may seem substantial, the long-term cost savings justify the expense. By reducing labor costs, minimizing material wastage, and optimizing polishing efficiency, these machines offer a compelling return on investment for businesses of all sizes.

Applications of Hinge Auto Polishing Machines

Hinge auto polishing machines find applications across a wide range of industries where polished hinges are integral to product functionality and aesthetics.

Manufacturing Industries

In manufacturing industries such as electronics, appliances, and consumer goods, hinge auto polishing machines streamline production processes by ensuring that hinges meet precise quality standards before assembly.

Automotive Industry

In the automotive industry, where hinges play a critical role in vehicle functionality and design, hinge auto polishing machines are essential for achieving flawless finishes on hinges used indoors, trunks, and hoods.

Furniture Industry

In the furniture industry, where hinges are prominent features in cabinets, wardrobes, and other furniture pieces, hinge auto polishing machines enable manufacturers to enhance the visual appeal of their products while maintaining durability and functionality.

Considerations When Choosing a Hinge Auto Polishing Machine

Selecting the right hinge auto polishing machine requires careful consideration of various factors to ensure optimal performance and value for money.

Capacity and Throughput Requirements

Assessing the production volume and throughput requirements is crucial when choosing a hinge auto polishing machine. Selecting a machine with sufficient capacity to handle anticipated production volumes will prevent bottlenecks and downtime.

Customization Options

Look for hinge auto polishing machines that offer customization options to accommodate different hinge sizes, shapes, and materials. Flexibility in polishing parameters and tooling options will enable you to meet diverse polishing requirements efficiently.

Maintenance and After-sales Support

Opt for hinge auto polishing machines from reputable manufacturers that provide comprehensive maintenance services and after-sales support. Regular maintenance and prompt technical assistance are essential for maximizing machine uptime and prolonging its operational lifespan.

Conclusion

Hinge auto polishing machines represent a significant advancement in polishing technology, offering unparalleled efficiency, consistency, and cost-effectiveness in achieving polished hinges across various industries. By understanding their operation, advantages, applications, and key considerations, businesses can make informed decisions when investing in these indispensable polishing solutions.