Introduction to Hinge Bending Tool

Definition and Purpose

A hinge bending tool is a specialized device designed to accurately bend hinges, which are pivotal components facilitating rotational movement between two parts. It serves a crucial role in precision engineering by enabling controlled and uniform bending of hinges to meet specific design requirements. The tool operates on the principle of controlled force application to achieve desired angles and reduce manual effort, streamlining the hinge manufacturing process.

Advancements in Precision Engineering

With rapid advancements in precision engineering, the demand for tailored and high-performance hinges has soared. Traditional manual bending methods are often labor-intensive and prone to errors, leading to inconsistencies in hinge performance. The introduction of the hinge bending tool has revolutionized the industry, allowing engineers to create hinges with unparalleled accuracy and efficiency, thereby elevating the overall quality of products and systems that rely on such hinges.

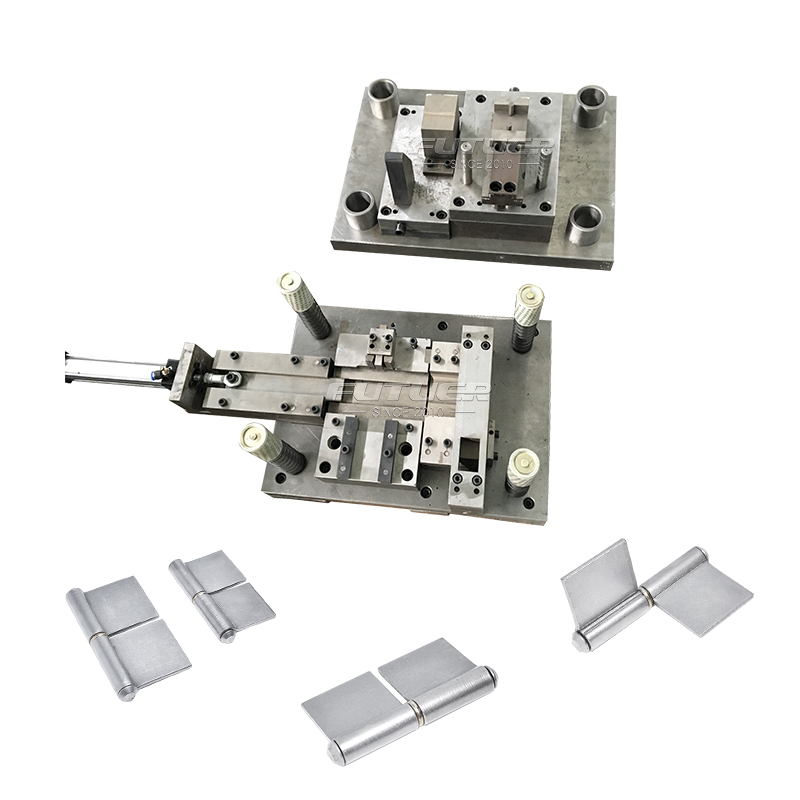

flag hinge bending mold

The Mechanics Behind Hinge Bending Tools

Structural Components and Design Principles

A typical hinge bending tool consists of several essential components, including a sturdy base frame, an adjustable bending arm, and a clamping mechanism to secure the hinge in position. The bending arm is often equipped with precision scales or digital readouts to facilitate angle adjustments with utmost precision. The tool's design prioritizes stability and rigidity to ensure consistent results during the bending process.

Utilizing Mechanical Advantage for Efficient Bending

Hinge bending tools leverage mechanical advantage to achieve precise bending. By applying force at specific points along the hinge arm, the tool enables incremental adjustments, allowing engineers to control the bending angle with remarkable accuracy. The ability to calibrate the tool according to the desired hinge specifications ensures that the resulting hinges conform precisely to the intended design parameters.

Applications of Hinge Bending Tools

Versatility in Industrial Settings

Hinge bending tools find widespread application in diverse industrial sectors. From manufacturing heavy machinery and automotive components to crafting delicate electronic devices, the tool caters to a broad spectrum of industries seeking customized hinges to meet their specific needs. Its adaptability to various hinge sizes and materials makes it an indispensable asset in modern manufacturing processes.

Crafting Customized Hinge Designs

Innovation in hinge design is a hallmark of the hinge bending tool's utility. Engineers can now explore novel hinge configurations, optimizing them for unique applications. Whether it's designing hinges for space-constrained environments, ensuring smooth articulation in complex mechanical systems, or crafting aesthetically pleasing hinges for architectural purposes, the hinge bending tool empowers engineers to bring their creative visions to life.

Benefits and Future Potential of Hinge Bending Tools

Enhanced Efficiency and Accuracy

The most apparent benefit of hinge bending tools lies in their ability to enhance efficiency and accuracy in hinge manufacturing significantly. The elimination of manual guesswork reduces wastage and rework, streamlining production processes and resulting in cost savings. Moreover, the precise bending capability ensures that hinges function seamlessly, contributing to the overall reliability and longevity of products.

Exploring Innovations in Materials and Technology

As precision engineering continues to push boundaries, hinge bending tools are likely to evolve further. Innovations in materials, such as advanced alloys and composites, will require tools capable of handling diverse properties. Additionally, integration with digital technology, such as computer-controlled bending and machine learning algorithms, could unlock untapped potential, further pushing the boundaries of hinge design and manufacturing.

Conclusion

The advent of the hinge bending tool has ushered in a new era of precision engineering, revolutionizing hinge manufacturing and design processes across various industries.

Cooperating with Futuer to harness mechanical advantage and leveraging innovative technologies, our top-quality hinge manufacturing tools have become indispensable assets for engineers seeking to create customized hinges that meet stringent performance criteria!