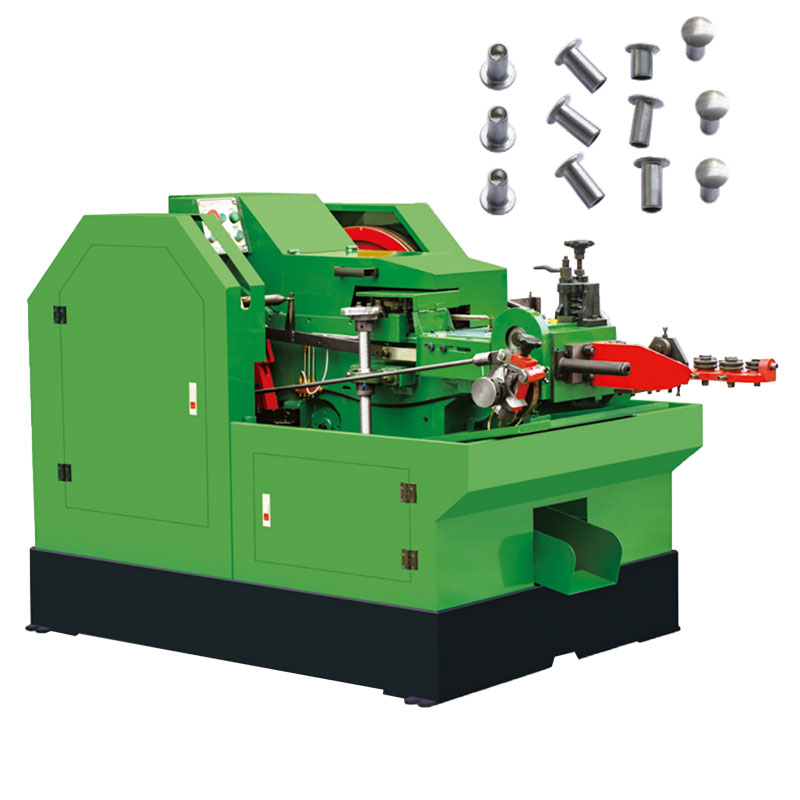

In the intricate realm of manufacturing, where precision is the ultimate goal, the function of a hole punching machine in the fabrication of semi-hollow rivet molding products is both crucial and intriguing. This specialized machinery represents a sphere where accuracy and efficiency come together to form the foundation of diverse industries.

The hole punching machine's role in semi-hollow rivet molding is significant. These machines are integral in creating precise perforations, enabling the flawless incorporation of rivets into various products. The importance of this process stems from its ability to improve structural stability and facilitate the secure assembly of components.

The Structure of Semi-Hollow Rivet Molding

Overview of Semi-Hollow Rivets

Semi-hollow rivets are a perfect example of the delicate balance between strength and weight in manufacturing. Unlike their solid counterparts, these rivets have a partially hollow shaft, which reduces weight without sacrificing structural stability. The hole punching process is vital in molding these rivets, ensuring that the hollow section is strategically positioned for optimal performance.

Significance of Accurate Hole Placement in Molding

The precision of hole placement is not just about aesthetics; it is a critical factor in determining the functionality of semi-hollow rivet molded products. Misaligned holes can lead to structural weaknesses, jeopardizing the reliability of the final assembly. Therefore, the precise alignment achieved by a hole punching machine is essential in maintaining the integrity of the rivet and the products it secures.

Progression of Hole Punching Technology

Traditional Methods vs. Modern Machinery

In the history of manufacturing, hole punching was once a labor-intensive task, dependent on manual processes prone to human error. The introduction of modern machinery transformed this scenario, bringing in automated systems that not only speed up the hole punching process but also enhance precision to new heights. The transition from manual to automated methods reflects the ongoing quest for perfection in manufacturing.

Advancements in Automated Punching Systems

Modern hole punching machines incorporate CNC (Computer Numerical Control) technology, providing unparalleled accuracy and consistency. These systems operate with meticulous control, ensuring each punch is executed with micron-level precision. The ability to program variable punching speeds and modify the die configuration adds versatility, allowing manufacturers to adjust the punching process to the specific needs of each semi-hollow rivet molding project.

Key Features of an Efficient Hole Punching Machine

Precision Engineering and CNC Technology

Precision engineering, combined with CNC technology, forms the core of an efficient hole punching machine. The synergy between these elements results in the creation of perforations that meet the most stringent tolerances. The CNC-driven precision ensures that each punch contributes to the perfect fabrication of semi-hollow rivets.

Variable Punching Speeds and Die Configurations

Advanced hole punching machines are characterized by their flexibility. Manufacturers can adjust punching speeds to accommodate different materials and thicknesses, avoiding deformations and material stress. The ability to switch between die configurations allows for customization, adapting the machine to the specific needs of semi-hollow rivet designs. This adaptability is a significant advantage in the rapidly evolving field of manufacturing.

Applications and Industries Benefiting from Hole Punching Machines

Automotive Sector

The automotive industry, with its continuous quest for lightweight materials and enhanced structural strength, benefits significantly from the precision offered by hole punching machines. From chassis components to interior fixtures, the use of accurately molded semi-hollow rivets contributes to fuel efficiency and overall vehicle performance.

Aerospace and Construction Industries

In the aerospace and construction sectors, where weight and structural integrity are paramount, hole punching machines have become indispensable. The ability to create precisely positioned perforations in semi-hollow rivets ensures that components used in aircraft and buildings meet the rigorous standards of safety and durability.

Conclusion

The unassuming hole punching machine plays a critical role in the fabrication of semi-hollow rivet molding products. Its contribution to the future of industries, where precision and efficiency are crucial, underscores the synergy between human creativity and technological advancement. As we continue to push the limits of what is achievable, the hole punching machine shapes the foundation of modern manufacturing.