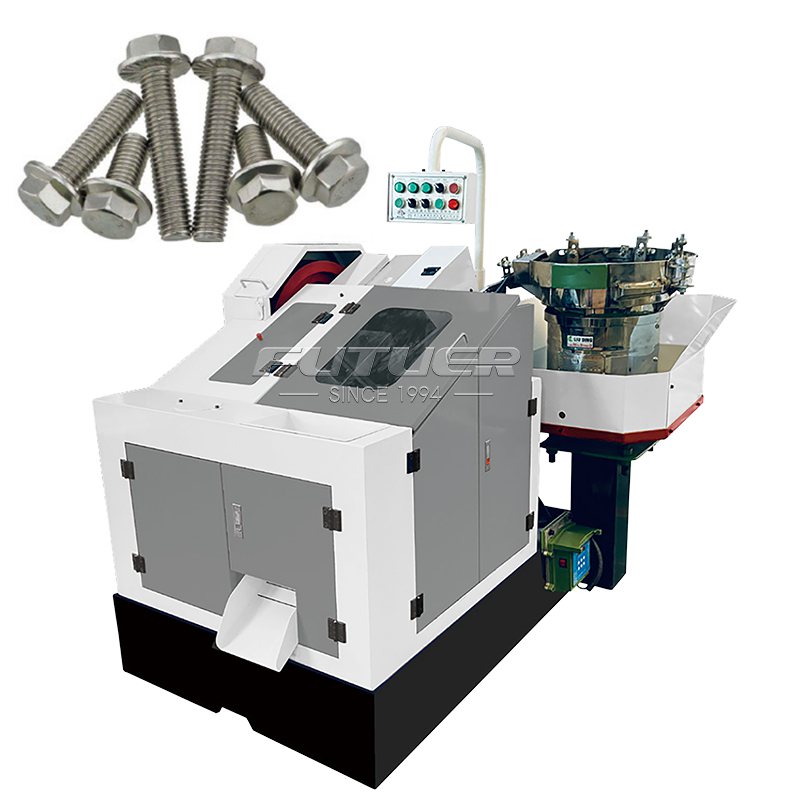

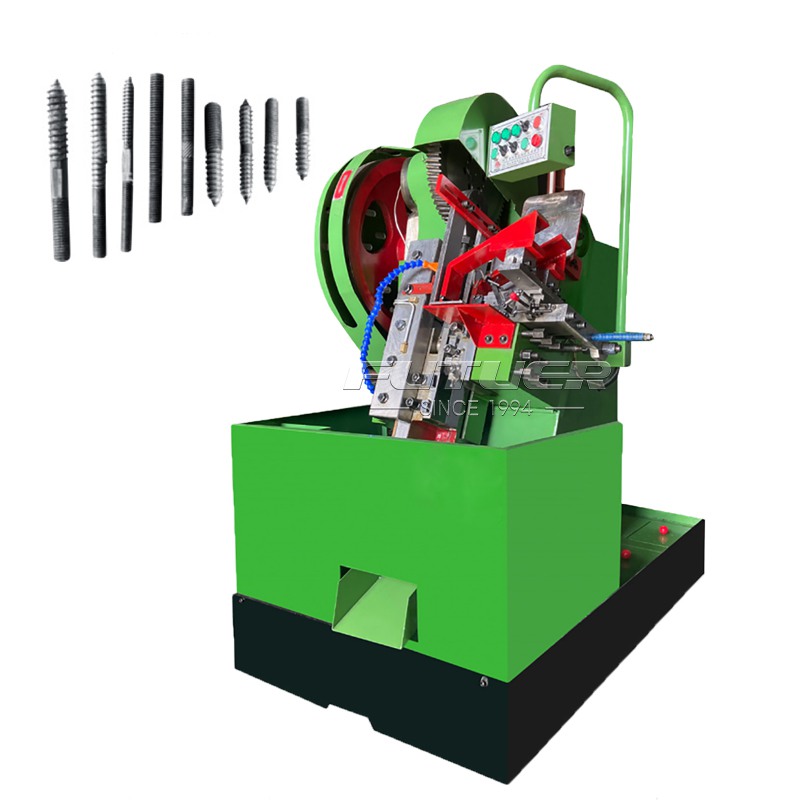

Thread rolling machines, integral to the manufacturing industry, significantly contribute to the formation of nuts and bolts that underpin our daily lives. These machines are crucial in creating threaded connections, combining accuracy and durability into a single process. This article provides a comprehensive overview of thread rolling machines for the manufacturing sector.

Thread Rolling Machine: Mechanism and Components

Machine Structure Overview

Thread rolling machines have a complex design, consisting of numerous interconnected parts. The central structure is a sturdy frame that houses the critical components. These components work in unison, similar to the gears in a clock, transforming raw materials into finely threaded products.

Key Component Functionality

Die Plates

The die plates, the central component of a thread rolling machine, create threads with remarkable precision. Made from hardened steel, these plates are responsible for shaping the raw materials into threads, balancing between durability and delicacy.

Feed Mechanism

The feed mechanism, a vital part of the machine, regulates the steady movement of material. It ensures a smooth flow, coordinating with the die plates to produce a consistent thread, a testament to engineering brilliance.

Pressure System

As the machine molds the steel, the pressure system applies a controlled force. The careful regulation of pressure determines the thread's quality. This is where the balance between power and precision becomes most apparent.

Advantages of Thread Rolling Machines

Precision and Consistency

Thread rolling machines are known for their precision, creating threads with microscopic accuracy. The consistency achieved is unmatched, ensuring each product meets the high standards set by these mechanical devices.

Material Savings and Increased Strength

In the context of manufacturing, thread rolling machines transform raw materials into threaded products. By cold-forming threads, these machines not only conserve material but also improve structural strength, producing threads that are durable and long-lasting.

Environmental Impact and Sustainability

In response to increasing environmental concerns, thread rolling machines are designed to be eco-friendly. The cold-forming process reduces waste, contributing to a more sustainable manufacturing process. Sustainability is, therefore, not just a benefit but a core feature of every thread produced.

Applications of Thread Rolling Machines

Automotive Industry

Thread rolling machines have a significant role in advancing the automotive industry. From the bolts securing engines to the detailed threads in braking systems, these machines have a profound impact on every vehicle's design.

Aerospace Sector

In the aerospace industry, where precision is critical, thread rolling machines are key to ensuring safety. They create components that withstand the rigors of space travel and contribute to the future of aviation.

Construction and Heavy Machinery

In the construction industry, thread rolling machines are instrumental in creating structures that endure over time. From skyscrapers to heavy machinery that shapes our landscapes, these machines form connections that underpin our civilization.

Choosing the Right Thread Rolling Machine

Selection Factors

Material Compatibility: Understanding the properties of different materials is the first step in selecting the right machine. Different alloys require different handling, and the thread rolling machine must be capable of working with each one effectively.

Production Volume: In the manufacturing industry, production volume is a crucial factor. The appropriate thread rolling machine must be able to handle the demands of mass production without compromising on quality.

Thread Type and Size: Threads come in various shapes and sizes. The selected thread rolling machine must be versatile and capable of creating both delicate and robust threads, ensuring a perfect fit for every application.

Maintenance and Operation Considerations: Maintenance is critical to the longevity of a thread rolling machine. Regular upkeep, lubrication, and monitoring for signs of wear and tear ensure the machine remains reliable, producing threads with consistent precision.

Conclusion

The thread rolling machine, often overlooked in favor of more prominent machinery, plays a vital role in the manufacturing industry. From forming the core components of our vehicles to strengthening the structures we live in, these machines are pivotal in creating connections, threading the fabric of our modern world with unwavering precision and strength.